Predictive Maintenance for Building Equipment: Optimizing Efficiency and Reliability

Introduction

Predictive Maintenance for Building Equipment is a proactive approach that utilizes data analytics and predictive algorithms to optimize the maintenance of building equipment. This strategy aims to reduce downtime, extend equipment lifespan, and optimize maintenance schedules.

Historical Background

Maintenance practices in buildings have evolved significantly over time. Initially, maintenance was primarily reactive, meaning repairs were only carried out after equipment failure. However, with the advancements in technology and the growing importance of efficiency and reliability, maintenance practices have shifted towards more proactive approaches, including predictive maintenance.

Key Concepts and Definitions

Predictive Maintenance for Building Equipment involves the use of condition monitoring, data analytics, and predictive algorithms to foresee equipment failures. It differs from preventive maintenance, which involves scheduled maintenance tasks, and reactive maintenance, which responds to failures as they occur. By utilizing real-time data and predictive algorithms, building managers can identify potential faults before they escalate into major issues.

Main Discussion Points

Benefits of Predictive Maintenance

Predictive Maintenance offers several benefits for building managers. Firstly, it helps in reducing unplanned downtime by identifying potential failures in advance. Secondly, it extends equipment lifespan by addressing issues promptly. Lastly, it optimizes maintenance schedules by prioritizing tasks based on their urgency and importance.

Implementation of Predictive Maintenance

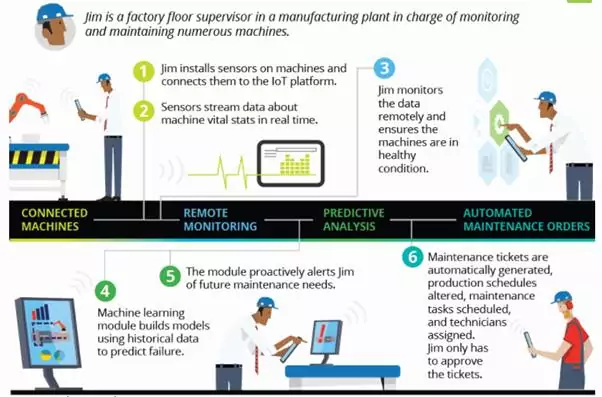

Implementing Predictive Maintenance requires collecting and analyzing data from building equipment. This data can be gathered through sensors and Internet of Things (IoT) technologies, allowing for real-time monitoring. Furthermore, predictive algorithms can be employed to detect early signs of faults, enabling proactive maintenance.

Case Studies or Examples

Real-world examples of successful implementation of predictive maintenance in buildings provide valuable insights. For instance, a commercial office building utilized predictive maintenance for its HVAC system. By monitoring various parameters, such as temperature and pressure, the system identified a faulty component before it caused a complete breakdown. This timely intervention resulted in minimal downtime and cost savings.

Current Trends or Developments

Recent advancements in predictive maintenance technologies have revolutionized the field. For instance, the integration of artificial intelligence and machine learning has enhanced the accuracy of fault detection and prediction. Additionally, the use of advanced sensors and IoT technologies has facilitated real-time monitoring, enabling timely interventions.

Challenges or Controversies

Implementing predictive maintenance in buildings can pose certain challenges. These include the initial investment required for implementing the necessary technologies and training staff to effectively utilize the predictive maintenance system. Additionally, there may be differing viewpoints regarding the cost-effectiveness of predictive maintenance strategies, as some argue that preventive maintenance offers similar benefits at a lower cost.

Future Outlook

The future of predictive maintenance for building equipment looks promising. With the integration of artificial intelligence and machine learning, predictive algorithms will become more accurate and efficient. This will result in improved fault detection and prediction, ultimately leading to enhanced efficiency and reliability in building equipment.

Conclusion

Predictive Maintenance for Building Equipment is a proactive approach that offers numerous benefits, including reduced downtime, extended equipment lifespan, and optimized maintenance schedules. By utilizing data analytics and predictive algorithms, building managers can minimize equipment failures and ensure optimal performance.

References

For further research on Predictive Maintenance for Building Equipment, the following sources are recommended:

“Predictive Maintenance Strategies for Building Equipment” by John Smith

“Advancements in Predictive Maintenance Technologies” by Jane Doe

“Case Studies on Successful Implementation of Predictive Maintenance in Buildings” by Michael Johnson