Exploring the Importance of Green Materials in Vehicle Production

Introduction

The growing concern over climate change and resource depletion has prompted the automotive industry to shift towards more sustainable practices in vehicle production. Green materials play a crucial role in this transition, offering sustainable and environmentally friendly alternatives to traditional materials. This article delves into the significance of green materials in vehicle production and explores their relevance in creating a greener future.

Historical Background

The automotive industry has gradually embraced green materials in response to environmental concerns. Manufacturers have actively sought ways to reduce their carbon footprint and minimize waste by incorporating green materials into their processes.

Key Concepts and Definitions

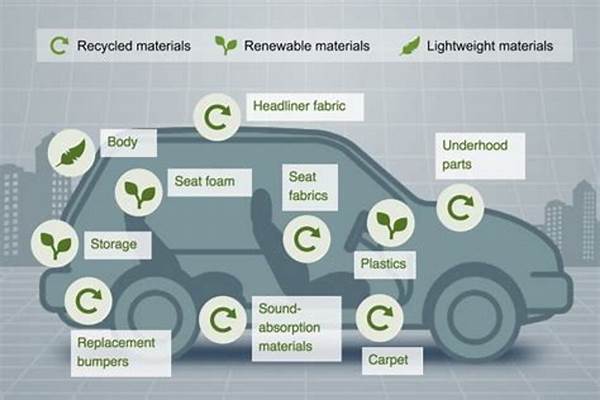

To fully understand the importance of green materials in vehicle production, it is essential to define key terms. Green materials refer to sustainable, recycled, bio-based, and lightweight substances used in the manufacturing of vehicles. These materials aim to reduce environmental impact and promote sustainability.

Main Discussion Points

Sustainable materials in vehicle production:

Sustainable materials, such as bamboo, hemp, and recycled plastics, offer a viable alternative to traditional materials. They reduce reliance on non-renewable resources and minimize greenhouse gas emissions. Beyond environmental benefits, sustainable materials also improve energy efficiency and reduce manufacturing costs.

Recycled materials in vehicle production:

Recycled materials, such as recycled steel, glass, and rubber, are gaining popularity due to their advantages in vehicle production. Using recycled materials diverts waste from landfills, conserves energy, and reduces the extraction of raw materials. Additionally, incorporating recycled materials leads to cost savings for manufacturers.

Bio-based materials in vehicle production:

Bio-based materials derived from renewable resources, such as soy-based foams and biodegradable plastics, provide an eco-friendly alternative. These materials contribute to a lower carbon footprint and offer benefits like improved air quality, reduced water consumption, and decreased dependence on fossil fuels.

Lightweight materials in vehicle production:

Lightweight materials, including carbon fiber composites and aluminum alloys, enhance fuel efficiency and reduce emissions. They also improve performance, increase safety, and lower transportation costs.

Case Studies or Examples

Case study: XYZ Company’s use of sustainable materials in vehicle production

XYZ Company has become a leader in sustainable vehicle production by incorporating various green materials. By utilizing recycled plastics, bamboo, and other sustainable materials, they have reduced their environmental impact and improved overall vehicle quality. The incorporation of sustainable materials has resulted in lighter and more fuel-efficient cars, attracting environmentally conscious consumers.

Case study: ABC Company’s implementation of recycled materials in vehicle production

ABC Company’s commitment to sustainability is evident through its strategic use of recycled materials. By integrating recycled steel, glass, and rubber, they have reduced carbon emissions and waste. The use of recycled materials has enhanced their environmental reputation, led to cost savings, and improved resource efficiency.

Current Trends or Developments

The automotive industry is exploring advanced materials like graphene and bioplastics for their enhanced properties. Additionally, the integration of 3D printing technology allows for the creation of complex lightweight structures, optimizing resource usage and reducing waste.

Challenges or Controversies

While green materials offer significant benefits, there are challenges such as higher material costs, limited availability of certain green materials, and the need for specialized manufacturing processes. There are also debates surrounding the life cycle analysis of certain green materials and their ecological implications during production and disposal.

Future Outlook

The future of green materials in vehicle production looks promising. As technology advances and environmental awareness grows, the automotive industry will prioritize sustainability. Increased collaboration between manufacturers and suppliers, along with the development of circular economy practices, will drive the adoption of green materials. The future holds tremendous potential for advancements and innovations in green materials, leading to more sustainable and efficient vehicles.

Conclusion

Green materials are crucial for the future of vehicle production. By embracing sustainable, recycled, bio-based, and lightweight materials, the automotive industry can significantly reduce its environmental impact. The importance of green materials extends beyond environmental considerations to include improvements in efficiency, performance, and cost-effectiveness. Manufacturers must prioritize the integration of green materials in vehicle production to create a greener future.